Top Applications of Metal Pressing in Various Industries

Metal pressing and stamping is a necessary metal service in a number of different industries, used to mould products into desired shapes. From kitchen appliances to aeroplane wings, metal materials undergo pressing, stamping and cutting during the production process to create products or components.

In this article, we will explore the diverse applications of metal presswork across various industries, exploring the key role it plays in producing goods and products and the importance of precise and effective pressing.

What Is Metal Pressing?

Metal pressing is a general metalworking term that refers to using machinery or a metal press to manipulate metal sheets or components into a wide array of different shapes. It encompasses a number of different metal presswork techniques, including stamping, punching, blanking, bending, forming, embossing and deep drawing.

There are many presswork tools and equipment, each suited to different pressing and shaping needs. Producing metallic items by hand was once a costly and time-consuming process. However, metal presses have sped up production times while enhancing precision, making it an essential process, particularly for intricate metalwork.

Where Is Metal Presswork Common?

As metal pressing is such a highly versatile service, it is a critical process in many sectors. Let’s take a look at the top industries where metal pressing is used and why it is important.

Currency Production

One of the most long-standing industries where metal pressing, stamping, and other metal-cutting services have been at the core of production is currency manufacturing. Since ancient times, currency has been created from metal. Originally, basic presswork tools were used to press the metal and create a recognisable design that demonstrated the value of the coin.

Nowadays, currency production has made significant advances, with metal pressing and stamping shaping coins into various sizes and intricate designs.

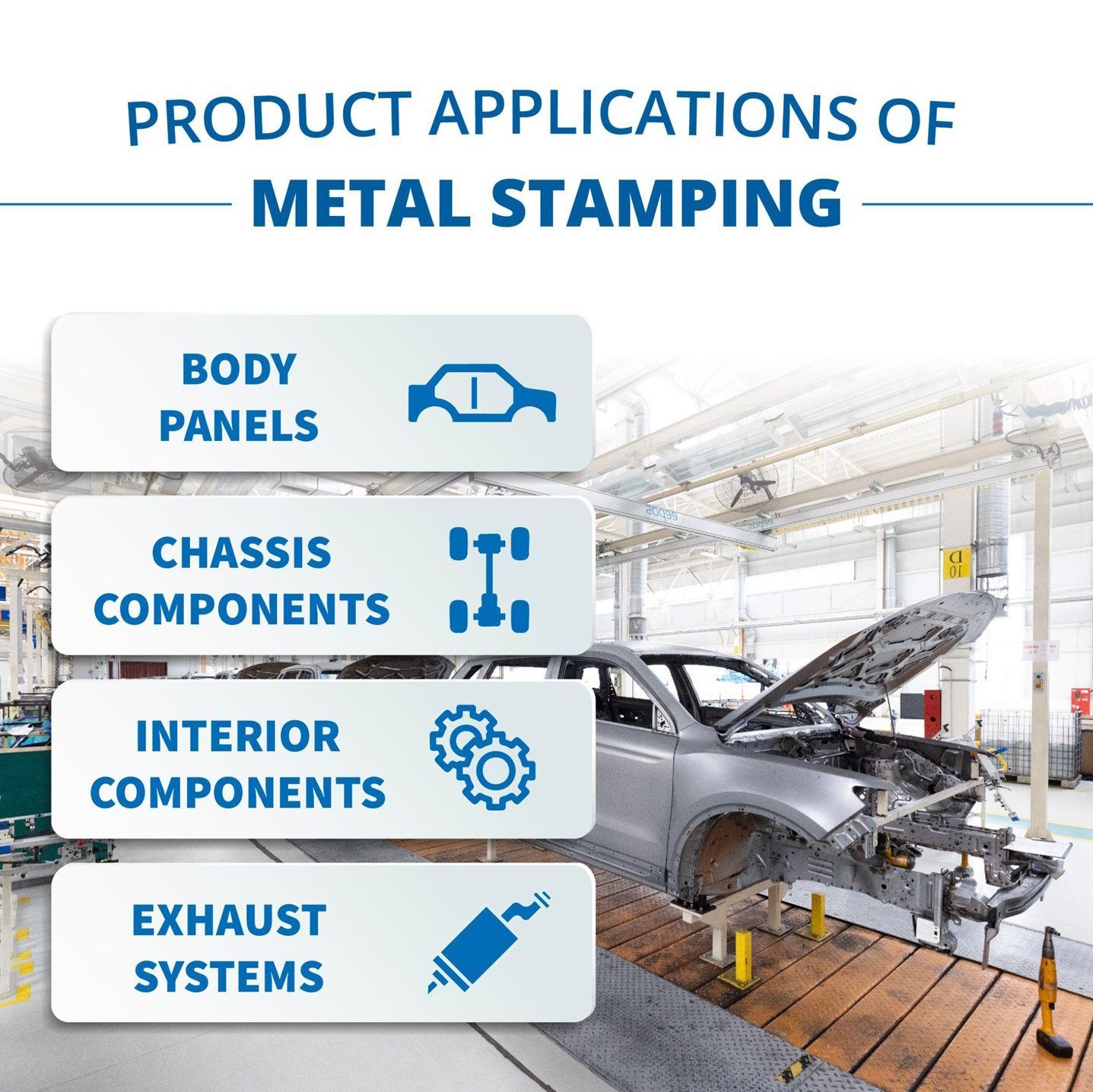

Automotive

Metal pressing is an essential process in the automotive industry, used to manufacture many metal components of vehicles, such as body panels, hinges, engines and more. Flat metal sheets are shaped using specialised pressing machinery and die stamping to achieve the desired form.

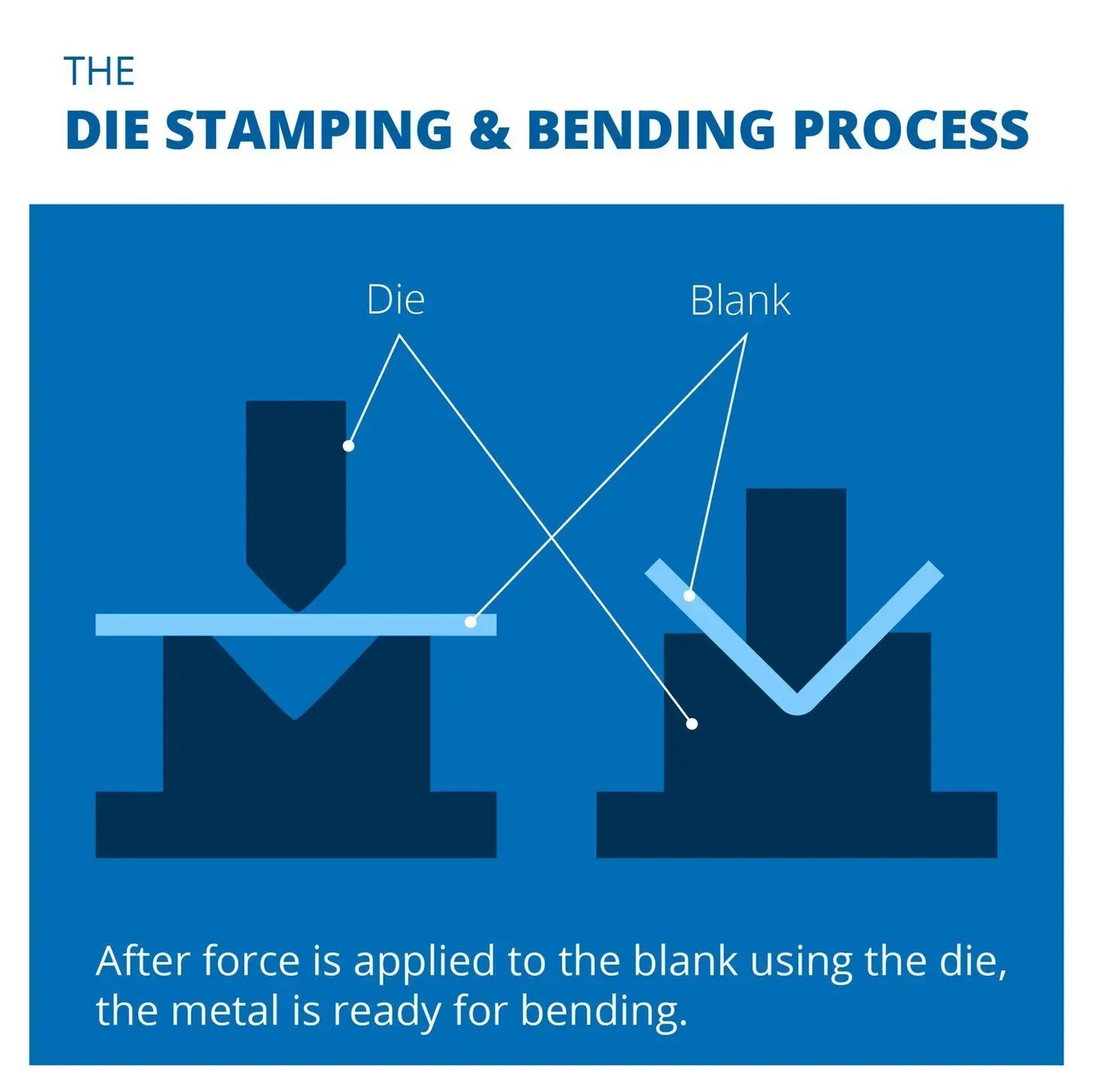

Die stamping is a type of metal pressing that involves cold-forming a sheet or strip of metal, known as a blank, using one or more dies. When force is applied to the blank, the metal becomes malleable. It can then be bent into specific shapes.

While the principles of metal pressing have remained the same since the Industrial Revolution, the technology has evolved, making metal shaping a much more efficient process. Shaping metal through blanking, bending, punching and piercing materials is a particularly laborious and complex process. However, the use of multiple dies has streamlined this, making it more time and cost-effective.

Medical and Healthcare

In the medical field, metal is a common material used for a number of tools and devices. Given the gravity of medical applications, this sector requires high-quality materials manipulated into precise configurations. For metal tools to be safe for use, they must undergo stringent processes to ensure sterility, preventing infections that could risk patient health.

Likewise, metal devices must be manufactured to be long-lasting. For example, pacemakers, which have a metal casing, often remain in the body for up to 15 years. Metal pressing and stamping provide a highly durable solution that outlasts other materials, like thermoplastics, proving a better option for long-term use.

Aerospace

The aerospace industry is another sector with particularly stringent regulatory standards, which require strict quality controls and comprehensive documentation to demonstrate compliance with the latest laws and requirements.

In metal production, many components must go through metal stamping to ensure their shape is accurate. Typical components include fuel systems, engine controls, sensors, switches and much more. Consistency is essential when producing these parts, and metal stamping ensures they fit together precisely for safe and efficient aircraft operation.

Oil and Gas

In the oil and gas industry, mechanical failure can pose significant risks due to the highly flammable nature of these resources. For this reason, the industry is subject to high-quality controls for safety and efficiency.

The metal used to contain gas or oil can be subjected to a number of challenging environmental conditions, such as light, temperature, corrosion and volatile materials, all of which it must effectively withstand.

Metal stamping is often used for parts such as handles, brackets, and sealing components. Metal stamping is favourable for these elements as they require precision and durability, ensuring they will not break down during use, even in harsh or hazardous conditions.

Appliance Production

Metal pressing equipment is used to craft metal parts for all appliances, from dishwashers to fridge freezers and ovens. Household appliances often contain various components that undergo metal pressing and stamping to achieve their form, from internal electrical parts to external designs.

Appliance production is an industry that greatly benefits from metal pressing due to its enhanced production rates and reduced costs, enabling home appliances to be produced at a rate that meets customer demand. In 2023, over 15 million large appliances and more than 60 million small appliances were sold in the UK.

Power Generation

Fabricated metal components are essential in many types of power generation, from traditional combustion power to renewable energy. Due to its strength, durability and versatility, metal can withstand the weather and wear that these unique environments bring. Much of the power generation equipment work with small components, such as transformer components and generator parts, as well as larger parts like solar panels and wind turbines.

Discover Cotmor Tool and Presswork’s Pressing Services and Presswork Tools

At Cotmor Tool & Presswork, we have over 60 years of technical experience in providing metal presswork and metal cutting services. Our extensive range of metal presses and presswork tools, combined with our highly qualified and experienced team, allows us to handle the entire process, from design and development to prototype production and the final product.

Get in touch with us to tell us about your project and how we can help you create your ideal metal pressing solution that meets your budget and timescale.