Cotmor has supplied OEM and First Tier customers in the metal pressings industry for over 70 years and can now offer Electrical laminations and cut coils after acquiring the company formerly known as Redlaw Shearing. From our extensive 15000 sq ft manufacturing and stockholding facility here in Brierley Hill.

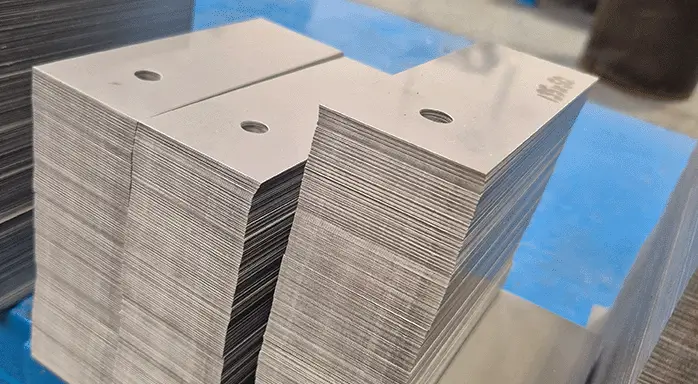

We offer a fast turnaround in grain and non-grain-oriented electrical steels ranging from 0.23mm, 0.30mm – 0.35mm thicknesses. We understand the importance of supplying high-quality laminations with a quick turnaround at a competitive price. Our quality standards are maintained under ISO 9001.

Any enquiries, large or small, will receive our immediate attention. Email sales@redlawelectricallaminations.co.uk or sales@cotmor.co.uk