Deep drawn

Presswork

When the depth is greater than the diameter

Different from other types of metal presswork, deep drawn presswork is specially designed to create metal pieces that have a depth greater than their diameter. This process is often precise, requiring an expert hand to create very specific pieces.

Utilising our over 60 years of experience, our team at Cotmor Tool and Presswork are talented in deep drawn metal presswork. Using our machine with 400-tonne press capacity, including an air cushion and a generous 1000 x 1000mm bed area, the Cotmor Tool and Presswork team can produce deep drawn pressings up to 200mm deep.

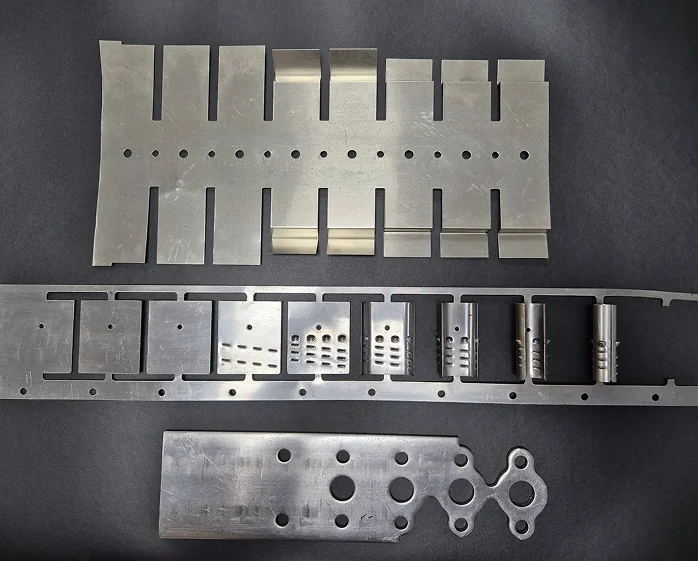

Progression

presswork

Working with progression presswork systems

With some metal presswork, achieving the intended result isn’t as simple as using one stamp. You may need a large number of components, which can be costly in terms of both time and money. Thankfully, our professional progression presswork systems at Cotmor Tool and Presswork allow us to maximise efficiencies in both, helping you to get the components you need as soon as possible.